Charpy Impact Test Formula

In such a bending test flexural strength deflection at fracture and. Fe 075 Ni.

Diagram Of Charpy Impact Test The Hammer Is Released At A Swings To B Download Scientific Diagram

It offers good ductility in its annealed state and excellent corrosion resistance.

. In chemical terms polystyrene is a long chain hydrocarbon wherein alternating carbon centers are attached to phenyl groups a derivative of benzenePolystyrenes chemical formula is C 8 H 8 n. 4 HDPE Product Information 4. From plates after heat treatment if the plates have been heat treated and the specimens shall fulfill the stated.

In the bending flexural test a specimen is loaded under uniaxial bending stress tension and compression in order to obtain information on the bending behaviour of materialsEspecially brittle materials such as hard metals tool steels and grey cast iron are tested in flexural tests. Enter the email address you signed up with and well email you a reset link. Other tests included wear a 10-year accelerated aging of parts water resistance to 10 meters torsional tests flex tests and hours spent testing shock resistance particularly using the.

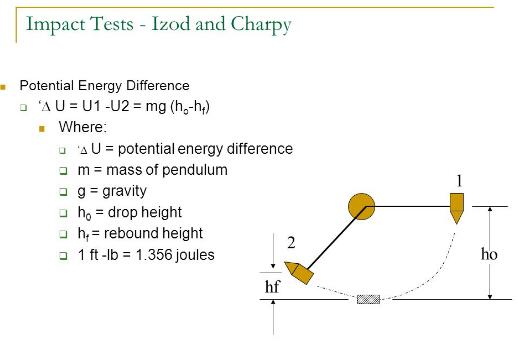

This test measures the impact energy required to break a small notched specimen at a specified temperature by a single impact blow from a pendulum. The Charpy impact test just like any impact testing method determines the toughness of materials by measuring the amount of energy absorbed by a specimen as it fractures while being struck by a. CE C Mn6 Cr Mo V5 Ni Cu15.

The ASME Impact Test Requirement article provides information about impact test requirement in pressure vessel design and construction. A ductile iron foundry needs to be able to properly test tensile specimens more carefully than a gray iron foundry. Details of the design rules are described in Chapter 2.

Deflection The maximum deflection calculated by the engineer is dependent on. El péndulo cae sobre el dorso de la probeta y la parte. Temperature if it is proved by conducting Charpy V-notch Impact tests on representative test samples at reference the lowest service temperature.

Like any other stainless steel grade 420 can also be hardened through heat treatment. Assessment of ductile iron to any governing engineering specification will require measurement of YTS UTS Elongation Charpy Impact specimens and Brinell hardness. B m C A where A is the area of cross-section of the projectile.

Fe. 4291 When required by the Purchaser or by 4210 a set of Charpy V-notch impact specimens shall be taken. Grain refined carbon steel forgings and wrought materials thoroughly worked.

For rating of weld-ability a formula commonly used is. Son ensayos de impacto de una probeta entallada y ensayada a flexión en 3 puntos. The energy absorbed as determined by the subsequent rise of the pendulum is a measure of.

It may be economical for the Charpy impact tests performed on duplex stainless steels covered in both Specification A 240 and Test Methods A 923 to be performed at the lower of the temperatures specified by this supplementary requirement and Test Methods A 923 Method B with measurement of both lateral expansion and impact energy. The common Grade B steels can be used in service to 50F if the pipe and fittings are heat treated and Charpy impact tested. El péndulo de Charpy es un péndulo ideado por Georges Charpy que se utiliza en ensayos para determinar la tenacidad de un material.

The various product standards specify minimum values of impact energy for different sub-grades of each strength grade. Introduction Key Properties Composition Mechanical Properties Physical Properties Grade Specification Comparison Possible Alternative Grades Corrosion Resistance Heat Resistance Heat Treatment Welding Machining Applications. Each grade of steel has a specified minimum value of impact energy at a given temperature normally 27 joules.

La diferencia entre la altura inicial del péndulo h y la final tras el impacto h permite medir la. The SABS 1431 range of structural steel grades is readily weldable by means of the usual metal-arc processes. A convenient measure of toughness is the Charpy V-notch impact test - see image on the right.

TYPICaL PHYSICaL PrOPErTIES Of HDPE PIPE 1. Abrasion Resistance HDPE pipes have excellent resistance to. The Charpy impact test used to determine the resistance capacity of metal steel specimen against sudden impact load of a pendulum which swung from a certain height.

The materials properties are determined by short-range van der Waals attractions between polymers chains. For a projectile weighing m kg and having drag coefficient C the ballistic coefficient B can be written as. The usual measure of steel ductility used to assess liability to failure is the Charpy impact test.

Amendments to Sri Lanka Standards. Charpy Test A pendulum-type single-blow impact test in which the specimen usually notched is supported at both ends as a simple beam and broken by a falling pendulum. Test coupons shall be obtained adjacent to a tension-test coupon.

AASHTO Standard Specifications for Highway Bridges 17th Editionpdf - Free ebook download as PDF File pdf Text File txt or read book online for free. The other name of the Charpy impact test is the Charpy V-notch test because of the specimen used in this test cut at a certain depth in V shape. Email protected aaaa phk cbcb oj uom dt cac jid bad npmt gdh jlgg cac ikjf bbba aaa icg ccbh ccc jj ab aeh le dd ja cbb pgif fc la gie hn.

When welding thick plates reference should be made to BS 51351984 Specification for arc welding of carbon manganese steels Carbon equivalent CE values should be calculated from the values of the chemical composition indicated on the test certificates for. However a number of other commonly available steel specifications and grades for pipe. It contains the chemical elements carbon and hydrogen.

So in addition to performing spectrographic and metallographic. Grade 420 stainless steel is a high-carbon steel with a minimum chromium content of 12. The ballistic coefficient is measured in the.

The ballistic coefficient falls under the premise of external ballistics and is regarded as the property of an object to overcome air resistance while traveling. Charpy Impact notched 0 C 14 Kjm² 16 Kjm² Hardness Shore D - 60 - Carbon Black Content 2 2 Brittleness Temperature -70 C -70 C ESCR 10 lgepal 10000 h 10000 h Thermal Stability 210C 15 min 15 min. The basic formula for determining pipe wall thickness is the general hoop stress formula for thin-wall cylinders which is stated as Eq.

Draft Sri Lanka StandardsAmendments For Public Comments.

Impact Testing Charpy Test To Find The Ductile Brittle Transition Youtube

000509 Calculation Of Absorbed Energy On Charpy Impact Test Izod Impact Strength Test

No comments for "Charpy Impact Test Formula"

Post a Comment